Art Application System (AAS)

2008, Aluminum, Stainless Steel

3 X 6 X .875"

Finished watercolor box for BPL Mission 002

Art Application System (AAS)

2008, Aluminum, Stainless Steel

3 X 6 X .875"

Art Application System (AAS)

2008, Aluminum, Stainless Steel

3 X 6 X .875"

Art Application System (AAS)

2008, Aluminum, Stainless Steel

3 X 6 X .875"

Art Application System (AAS)

2008, Aluminum, Stainless Steel

3 X 6 X .875"

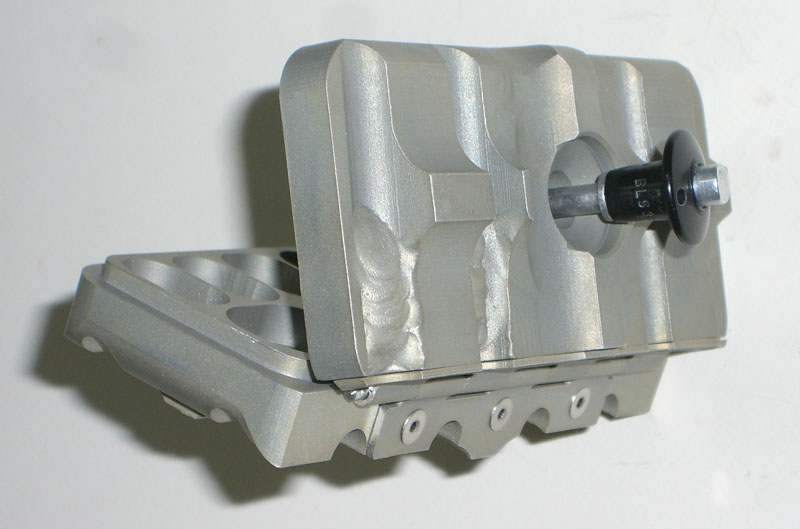

AAS Prototype production

Welded repair of Milling Error, inside.

AAS Prototype production

Welded repair of Milling Error, top.

AAS Prototype production

Inside of lid showing Milling Error, caused by slovenly measurement technique.

AAS Prototype production

Piano Hinge drilling.

AAS Prototype production

Inside of box at early pocketing stage- the two mixing troughs have not yet been cut.

AAS Prototype production

Showing use of pin to aid in holding open box during use

AAS Prototype production

Milling corners of outside of box.

AAS Prototype production

Milling Aerospacey-looking flutes into lid of box. This process led to a breach in the integrity of the structure which had to be mitigated by welding and cursing.

AAS Prototype production

Outside of top and inside of bottom, before hinge drilling.

Production of Art Application System (AAS)

Manufacturing documentation for production of a watercolor box used in BPL-002, Mission to China. This mission sent a BPL employee to China in an attempt to outsource labor, just like real manufacturers do. The plan was to generate touristic watercolor trinkets in China and then bring them back to the U.S. for distribution or storage. Doing this would enable BPL to realize its goal of being able to claim that it has outsourced a manufacturing process to China, while still having the product be American Made, and in the cheapest possible way. BPL "pre-sold" these watercolor postcard products to fund the trip. To enhance the uniqueness of this production strategy, BPL generated a prototype watercolor box, of an exceedingly rugged Aerospace-Grade™ aluminum construction. The process, typical for BPL, was not without setbacks, but in the end, all goals were met and exceeded, especially the unanticipated ones. See the

downloads section for a

production report in pdf format, and also for the Memo detailing BPL-002, Manufacturing Mission to China. A full report on that mission is due this summer.

This item is available for purchase at the

Brower Propulsion Laboratory Solutions store: https://bpl-solutions.com/product/7001

BPL home